At Allied, our growth and success go hand-in-hand with our commitment to quality. We are proud of our ISO 9001 Quality Systems Certification and its emphasis on customer satisfaction. Our goal is improved performance and unequaled service, which we achieve by:

Streamlining processes

Improving productivity

Shortening cycle time

Expanding production capacity

Increasing process flexibility

Ongoing Certifications

ISO certifications, scopes, policies and other related documents are available to all interested parties by request.

Forest Stewardship Council® (FSC-C012441)

Recent Awards

The Printing Industries Alliance – 2018 Franklin Luminaire Award

Sappi Paper 2018 North America Printer of the Year Finalist – Silver level

Hartford Business Journal’s 2017 Best of Business Award

The Advertising Club of Connecticut – 2016 Hall of Fame Inductee

Appleton Paper 2016 U360 Design Award

Hartford Business Journal’s Family Business Award – 2015 and 2016

Printing Industry of New England Merit Award for Self-Promotion – 2015 and 2016

Connecticut People’s Action for Clean Energy 2015 Business Leadership Award

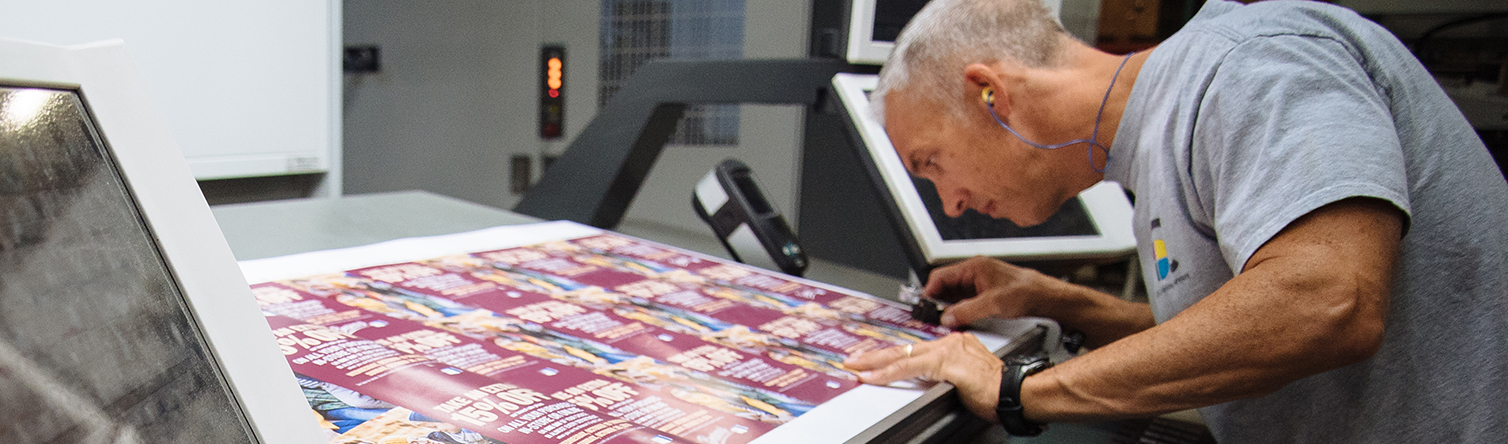

We are a G7 Master Qualified Printer:

We are experts in the fields of color management, process and quality control for proofing and printing, so you can be assured of color consistency across multiple platforms.

We rely on computerized process management:

Our system tracks jobs through every stage of production, while a dedicated production team monitors the status of every job and provides updates on every project.

We have our own on-site ink production facility:

You’ll know that you’re getting the best and most consistent color.

Proofreading is a priority:

We proofread every job multiple times at every point in the process to ensure that we’re printing exactly what you approved. Our clients appreciate us always catching the most minute syntax and spelling errors, especially between proof approval and press run. For you and for us, no detail gets overlooked.

-

Capabilities

we do it all. all under one roof.

learn more -

Careers

look for a job. find your passion.

search jobs -

Contact Us

need a miracle? or just a quote?

reach out